Description

A new Fluidampr on your diesel truck will not only protect your engine from destructive torsional vibrations but will also increase TORQUE & HORSEPOWER. High performance diesel engines running chips and programmers are exceptionally vulnerable to torsional vibrations. Save your crank & more by installing a new Fluidampr today.

Each time the air/fuel mixture inside a cylinder is ignited, the combustion event creates a torque spike that is applied to the crankshaft through the pistons and rods. This torque spike is so severe that it not only turns the crankshaft, it actually twists the crankshaft ahead of its normal rotation and then the crankshaft rebounds. This twisting action is known as torsional vibration. When these torque spikes get into phase with the natural frequency of the crankshaft assembly in the engine, critical torsional harmonic vibrations occur that are destructive to the bearings and crankshaft.

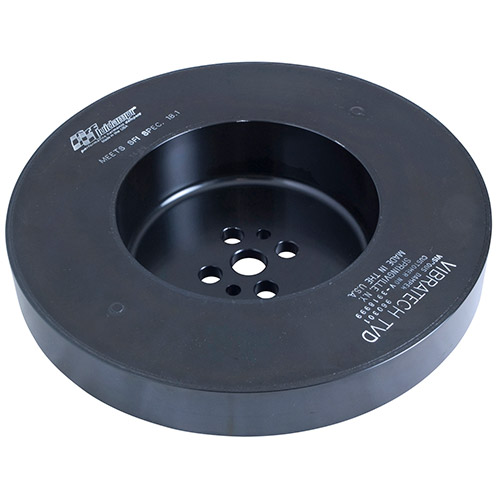

Each Fluidampr is manufactured to meet or exceed OEM specifications.

Unlike a stock elastomer harmonic balancer, Fluidampr performance dampers protect across a broad frequency range and can become more effective as magnitude increases throughout your RPM range. Each Fluidampr performance damper is designed for the engine application it is intended for.

Fluidampr performance dampers consist of a free rotating inertia ring inside a laser sealed outer housing within tight tolerance of each other. Both the inertia ring and the outer housing are computer balanced to exceed OEM specifications during manufacturing. Between the two, an area referred to as the shear gap is pressure injected with viscous silicone. This specialized silicone maintains stability across an extreme temperature range and provides superior heat dissipation.

As soon as your engine fires torsional vibration is present. To damp its destructive effects, the outer housing turns at engine RPM, while the inner inertia ring immediately self-centers and is free to be “shocked” by each torsional vibration event. As the inner inertia ring moves in-and-out of RPM with the outer housing, the shearing force through the silicone transforms the vibration to heat, which rapidly dissipates through the housing. Since the mass of the inertia ring is engulfed in a thin film of silicone and not directly connected to the crank, it can be calculated that only 2/3 of the total Fluidampr weight is rotating at RPM. For example, a 7.9lb Fluidampr for a Chevy LS1 only feels 5.3lbs at rpm.

The Fluidampr design originated from top race engine builders requesting Vibratech TVD (formally Houdialle and parent company to Fluidampr) to bring its viscous damper technology engineered for long-life, high power diesel applications to professional motorsports in the early-1980s to replace failing elastomer designs. Viscous torsional dampers are used today as original equipment on select luxury sports cars, light-duty diesel trucks and even military spec engines. Meanwhile, nearly all high power engines that move our economy depend on a viscous damper for superior protection, performance and durability.

Specifications:

- Material = Steel

- Black Zinc Finish

- O.D = 9-3/4″

- WT. lbs. = 23

- Bore Dia. = .750

- Length = 2.617″

- Balance = Internal